Tailored R&D results in a successful AGV project

When a terminal operator has a specific need, Kalmar goes the extra mile to provide a tailored solution. A recent R&D project with electric powered automated guided vehicles (AGVs) for PSA Singapore is living proof of this.

A long-time customer of Kalmar, PSA Singapore is the world’s busiest transhipment hub, accounting for almost one-seventh of the world’s total container transhipment throughput. To meet the future growth of global trade, it is currently constructing a new Tuas mega port, featuring totally automated terminal operations when the first phase opens in 2021.

To prepare for it, PSA has been testing AGVs in actual operations at its Pasir Panjang Terminal. In the final phase of the piloting process before moving to Tuas, the company ordered 22 electric powered AGVs. In May 2016, 18 of them were awarded to Kalmar. The Kalmar equipment was delivered at the end of June 2017 after an intensive 14-month project – tested and ready to go.

“The project combined new technology, new suppliers plus a new design provided by the customer and Kalmar. It was a good mixture of everything. The project took endless testing hours and a lot of fine tuning, but we managed to accomplish it all on time and in excellent cooperation with PSA,” adds Jukka Ristimäki, Product Manager, Intelligent Horizontal Transportation Solutions, Kalmar Automation and Projects, who was responsible for the development work.

“The AGV development project is one of our new product development projects demonstrating our ability to deliver a new solution for a fully automated terminal. It is a prime example of how Kalmar innovates and tailors products and solutions based on customer-specific needs,” says Ismo Matinlauri, Vice President, Solution sales and Marketing, Kalmar Automation and Projects.

Boosting sustainability through zero emissions

According to the Kalmar Port 2060 initiative, by 2060 all ports will run on renewable energy with zero carbon emissions and their production has tripled since 2013. This same vision for a sustainable future for cargo handling is shared by PSA as they opted for electric powered AGVs.

“We were extremely happy that the customer chose the electric powered design, because Kalmar’s strategy and green values match that. This was Kalmar’s first electrically powered horizontal transportation delivery,” Ristimäki continues. “The AGV completes Kalmar’s product offering. We can now offer an electric powered version featuring the FastCharge solution with a charging station both for automated shuttle carriers and AGVs.”

Kalmar navigation systems run on AGVs from five OEMs

In addition to the AGVs, Kalmar was awarded delivery of onboard navigation system software to all 22 new electric powered AGVs. This means that PSA’s current AGV fleet will use Kalmar’s onboard navigation system software. The first navigation software deliveries took place already in 2012.

Ristimäki points out Kalmar’s strengths: “We have a long history in automating terminal equipment with a high number of references. The Kalmar onboard navigation system has been tested and proven in many applications, and there are various position technologies for the customer to choose from. As the software is flexible and highly configurable, we can easily adopt new vehicle models and position technologies when required.”

These new electric powered AGVs for PSA complement Kalmar's automated intelligent horizontal transportation product offering. After the successful project and good experience with the AGVs, Kalmar now looks forward to offering AGVs to other customers, too.

"This was Kalmar’s first electrically powered horizontal transportation delivery."

What next?

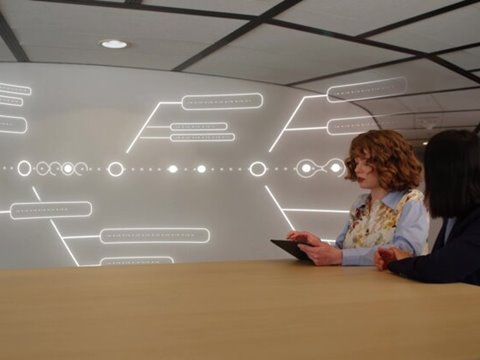

As you may well remember, in September 2017, Kalmar introduced Kalmar Key, an initiative driving the terminal industry's first automation platform with open interfaces. It provides architecture for building customised automation solutions using Terminal Logistics System as a basis. This all means that Kalmar Key enables a holistic view of data from the entire fleet of machines, allowing terminal operators to optimise their operations continually and with ease.

Whether you are looking for a tailor-made solution for your terminal or aiming for a more standardised ecosystem, Kalmar has the answer.

DOWNLOADS

Related articles

Further reading

Subscribe and receive updates in your email

Subscribe